Hydraulic Cylinders

Hystat are leading designers and manufacturers of hydraulic cylinders for a vast array of applications

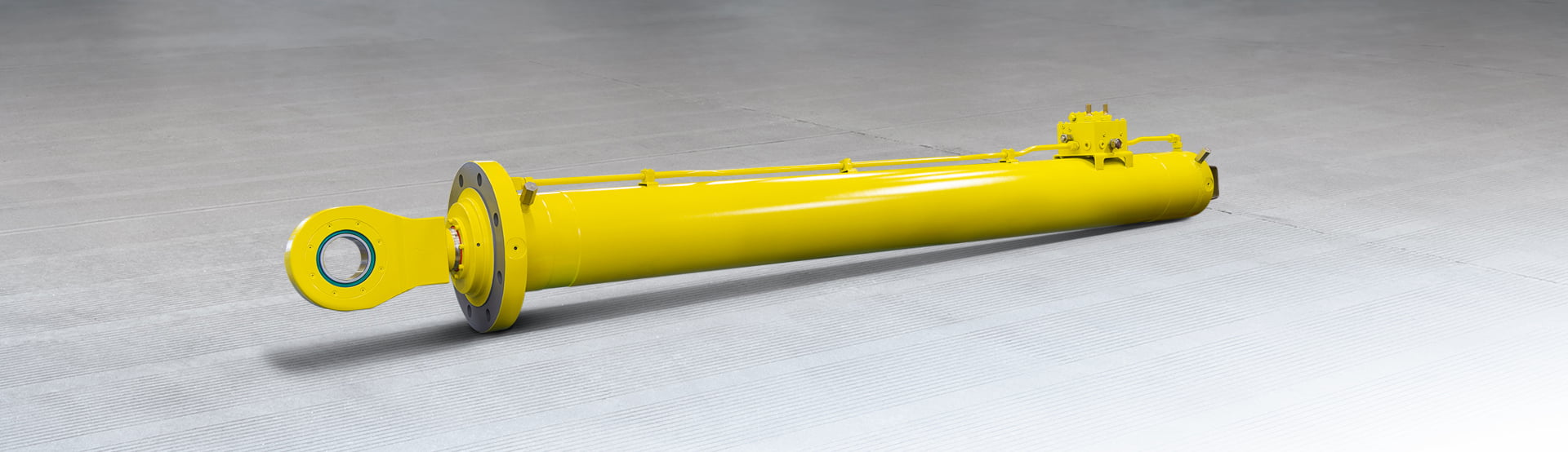

Hystat Hydraulic Cylinders are designed and manufactured in the UK. Hystat manufacture Hydraulic Cylinders for various applications with a large range of pressure, stroke, mounting detail, rod coating, external coating, materials of manufacture etc. Hystat ensure to manufacture a product to meet customer needs.

Hystat manufacture for the following markets:

Renewable, Energy, Marine / Offshore, Subsea, Industrial, Research & Development, Civil, Installation Equipment, Defence, and more

Optional Equipment:

Position Measurement, Proximity Switches, Manifolds, Stainless Steel Hydraulic Cylinder, Various Seal Types / Arrangements, Piping, Cushioning

| Stroke | up to 12,000mm |

| Rod Diameters | 10mm to 1,100mm |

| Bore Sizes | 20mm to 1,400mm |

| Pressure Range | 1 to 2500 Bar (Standard Ranges available) |

| Rod Coatings | Hard Chrome Plating, Nickel & HCP, HVOF, Ceramic, Laser Clad etc |

| Temperature Range | Various from -60° to over +100°C |

| External Coatings | Marine, Offshore, Subsea, Industrial etc |

| Mountings | Spherical Rod End, Eye, Clevis, Trunnion, Front/Rear Flange, Foot |

| Connection | Various available upon request |

| Approvals | LRQA, Lloyds, DNV, ABS, BV etc |

For over 40 years, we have been producing recognised standard range cylinders for interchangeability between manufacturers that are used throughout the world.

HDF 250 Bar Range to ISO6022 and CETOP R73H

ADF 160 Bar Range to ISO6020 and CETOP R58H

HDA 15 Bar Range to ISO6431 and CETOP RP43P

We now offer a standard range of Offshore, Marine & Subsea Cylinders rated at 250 bar and 320 bar. All designs conform to Lloyds Register, DNVGL and ABS Rules.

For more information please refer to our Technical Download section.

We have a wealth of experience that enables us to design cylinders specifically for use in arduous environmental conditions.

Utilising highly certified materials such as stainless steel rods and marine paint specifications to help withstand the wide range of temperatures and fluids, whilst maintaining optimal integrity and durability.

Typical Applications

These cylinders are designed for extreme and not readily accessible environments, so it is important that they are very robust and most of all reliable.

Therefore, preventing seawater ingress is of utmost importance. We offer highly certified materials including either high-grade stainless steel or ceramic coated rods and subsea paint specifications.

Typical Applications

Robust cylinders that are generally of a bolted construction and non-cushioned, but with generous safety factors.

Specially designed to suit the wide range of pressures, temperatures and often where consideration for high cycle fatigue is required. Overall, designed and manufactured to provide a competitively priced cylinder.

Typical Applications

Heavy-duty large bore (typically in excess of Ø1000mm) short stroke cylinders offering incredibly high output forces. Typically consisting of a forged alloy steel cylinder body and piston rod, precision machined with other components manufactured from certified materials without any welded joints.

Typical Applications

Cylinders designed with a series of progressively smaller piston rods nested within one another, ideal for hydraulic applications requiring a large reach in a compact collapsed space.

Single acting extend designs are more commonly used however they rely on an alternate retraction force, such as an external load or gravity. But we can offer double acting telescopic designs and constant force/constant speed (synchronised) designs upon request.

Typical Applications

This is the main area of our expertise! All we ask is the relevant information and application and we will work closely with you to deliver a design which meets your specific requirements.

Our highly skilled and experienced engineers work within our ISO9001:2015 quality management systems and are converse with all the major design codes and standards. This ensures complete peace of mind that the products we produce will be safe and provide a long service life.

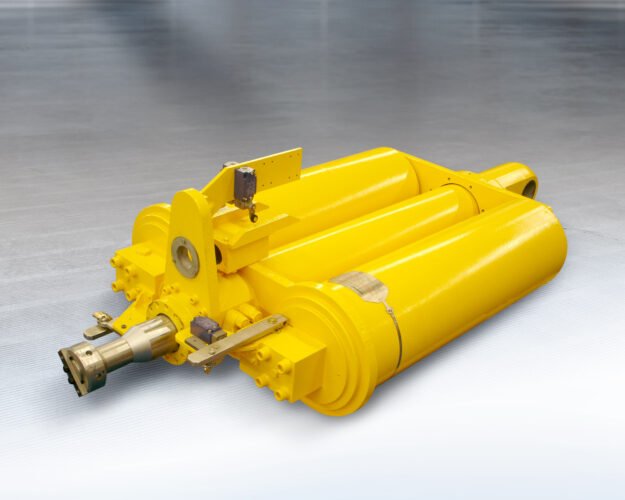

Whether you require a Non-Differential cylinder Spring Loaded cylinder, Rotary cylinder, Piggy-Back cylinder or even a Triple cylinder. With a comprehensive range from Ø20mm bore to over Ø1000mm bore and single strokes in excess of 10 metres. Internal or external linear transducers, cushioning, proximity switches and load holding valves to name a few.